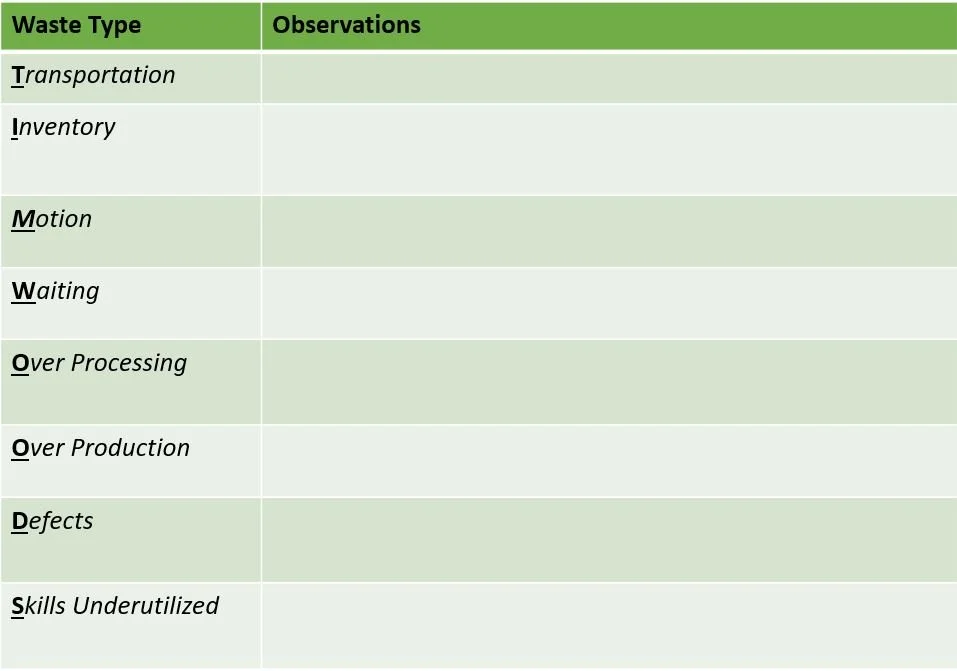

Waste Identification (TIMWOODS)

TIMWOODS is an easy-to-remember acronym used to distinguish between the 8 common wastes that occur in a process.

It is the first letter of each waste classification – Transport, Inventory, Motion, Waiting, Overproduction, Overprocessing, Defects, and Skills.

The TIMWOODS visualization tool serves as an effective way to identify areas of waste across a value stream.

By locating these 8 wastes, continuous improvement teams can target them for removal using lean tools, techniques, and methodology.

Transportation

Excessive movement of information, inventory, or material

Effects: Adds time to process, not value, misplaced materials during transport

Inventory

Excessive in the process of finished goods inventory. Backlog of Information, storage, handling, and carrying costs

Effects: Extra storage, repeated handling, stored items (lost, damaged, obsolete)

Motion

Any movement or step that does not add value to the product or process, personnel, intra-office

Effects: Increase process time, risk injuries, opportunities for error

Waiting

Long periods of inactivity for people, information, and upstream processes

Effects: workflow stoppage, downtime, inactivity periods

Over Processing

Doing more than is required by the customer. Using incorrect procedures, NVA steps, redundancies

Effects: increased cost to produce, more time required to service customer, greater risk of late product or service

Over Production

Producing more/sooner than the customer demand, more than what is required, “push”, before it’s needed

Effects: consumes resources unnecessarily

Defects

Errors in process or steps, product quality, associated inspection and rework, re-do, scrap

Effects: hidden costs, rejected product, dispute resolution, lost sales, disruption of normal process flow

Skills Underutilized

Not fully utilizing the talent and creativity of employees.

Effects: low employee morale, loss of creativity, turnover